Solving industry challenges through collaboration

Tara Hamid from Manufactures’ Monthly spoke to AMAC Director, Professor Gangadhara Prusty, to find out more about how AMAC is bringing industry and academics together to solve real-world engineering challenges, with the focus on advanced composite materials.

Call for New Postdoctoral Research Fellow

AMAC is seeking to appoint a Postdoctoral Research Fellow to manage and contribute to the Research Program “Design, Integration and Optimisation of composite structures”. The purpose of this appointment is to undertake and manage industry-focused research projects with the Centre’s partners.

Call for New PhD Candidates

ANU PhD opportunities:

UNSW PhD opportunities:

How to apply...

Apply for ANU positions

Applications should be submitted through the ANU Apply Online Portal by 18th September. The application should consist of a CV, a statement addressing the selection criteria, a nominated supervisor (Prof. Paul Compston); transcripts, graduation certificates and testamurs of previous tertiary study. Three referees must also be nominated. When choosing the scholarship type, please select other then enter ARC Training Centre Scholarship.

Potential candidates who wish to know more about the advertised ANU positions please contact Prof. Paul Compston, AMAC Centre Deputy Director, paul.Compston@anu.edu.au.

Apply for UNSW positions

Applications should be submitted to Professor Gangadhara Prusty, AMAC Centre Director, g.prusty@unsw.edu.au . The application should consist of a CV, a statement addressing the selection criteria, a transcripts, graduation certificates and testamurs of previous tertiary study. Three referees must also be nominated. All applicants are encouraged to use the HDR Self-Assessment Tool to help give an indication of your eligibility and competitiveness for a scholarship (please attach a screenshot of the outcome in your application).

Scholarship

Successful candidates will be eligible for a scholarship of $31,298 per annum under the Industrial Transformation Research Program (ITRP) scheme of Australian Research Council (ARC). There will be scope for additional top-up amounting from $5000-$10,000. The candidates will be provided with an industrial placement of 12 months during their research candidature.

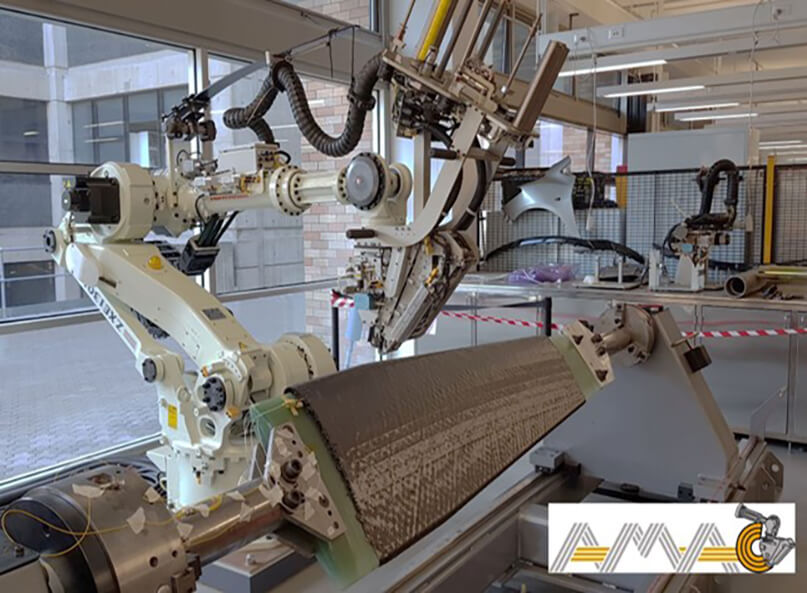

AMGC backs project to automate vehicle panel repair

The Advanced Manufacturing Growth Centre (AMGC) is supporting a collaborative project with Tradiebot Industries to deliver the world’s first automated vehicle panel repair system.

As part of the project, Tradiebot Industries will collaborate with the University of New South Wales (UNSW) ARC Training Centre for Automated Manufacture of Advanced Composites (AMAC) on developing a robotic control system to carry out physical repairs on damaged vehicle panels.

Tradiebot’s chief creator, Mario Dimovski said the project seeks to achieve a shift from manual production jobs, towards a more customised, smart and competitive manufacturing model, backed by high skilled workers.

Who are we?

The Australian Research Council (ARC) Training Centre for Automated Manufacture of Advanced Composites (AMAC) is established under the Industrial Transformation Research Program (ITRP) of the Australian Government. The University of New South Wales (UNSW) led Centre is a collaboration between the Australian National University (ANU), the Technical University of Munich (TUM) and nine industry partners. The partnering industries include the Ford Motor Company, Omni Tankers, Advanced Composite Structures Australia, Australian Institute of Sports, Carbonix, AFPT, FEI, the Australian Nuclear Science and Technology Organisation (ANSTO), and the Defence Science and Technology Group (DST-G).